| |

| CASTING |

|

|

| Overview |

The Cast house in Smelter Phase 1 of Vedanta Limited Limited, Jharsuguda has been designed to produce 550,000 tonnes of cast products per year. This cast house will cater to the evacuation requirement of both Line-I and II of Smelter in Phase-1. It is equipped with state of the art facilities and has a unique product mix of Standard Ingots, Extrusion Ingots (Billets), Sheet Ingots (Slabs) and Wire rods all housed in a single building.

The cast house team is a blend of qualified, young and energetic professionals and technicians along with highly experienced cast house professionals from both India and abroad. The average age of the group is 23 years and once the Cast house is fully functional it will have total man power strength of approximately 400. |

| |

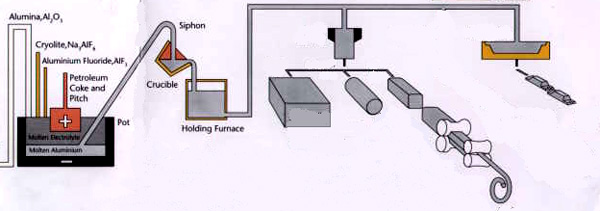

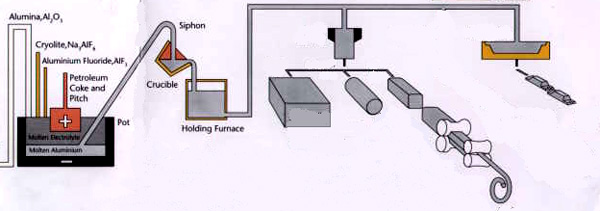

| Flow sheet of Aluminium Process and Technical Write Up: |

Molten aluminium from the electrolytic cells is tapped, transported and transferred to holding furnaces in Cast house with a specially designed vehicle from

M/s Hencon, Netherland. This is first of its kind in India and

it ensures fastest mode of metal transfer from pot line to

cast house with minimum loss of sensible heat.

Once the holding furnace in cast house is filled with molten

Aluminium from pot line, the same is prepared based on the product

requirement. Once desired composition is reached, the furnace is

skimmed to remove dross or surface impurities. After reaching the desired temperature and holding time, the furnace is ready for casting. When the respective casting lines are ready, casting is started.

The Cast House is equipped with modern electrically heated holding furnaces and Ingots Casting machines of state of the art technology. After filling the furnace with molten metal received from Pot rooms, the dross is skimmed out of the metal. All the furnaces are of tilting type fitted with hydraulic jacks. After metal preparation the furnace is tilted and molten aluminium runs to the Casting wheel of Ingots Casting machine through the launder. Metal samples are taken in each cast. The molten metal comes out of a series of nozzles located around the wheel. These nozzles feed metal into the moulds fitted on a conveyor. The water underneath the conveyor cools the metal in the moulds which result in formation of ingots of 22.7kg. These ingots are then cooled further, stacked into bundles, strapped and stacked on the floor automatically.

These stacks are shifted to the finished goods area from where it is dispatched as per sales order.

|

| |

| Facilities |

| Furnace |

10 furnaces are available each having 60 tonne of molten

aluminium holding capacity. All are electrically heated furnaces, equipped with hydraulic tilting mechanism

and laser sensor based automatic tilting control. The Electrical

furnaces facilitates clean and fumes free environment inside the

cast house. Out of the 10 furnaces, 4 are dedicated to three Ingot

casting lines, 2 for two Wire rod mills, 2 for one Sheet Ingot

Casting machine, and another 2 for one Billet casting machine.

The first furnace was commissioned on March 2008. At present 7 furnaces are operative.

|

| |

| Ingot Casting Machine (ICM) |

3 fully automated Ingot casting lines of Befesa make are available for casting of standard ingots. These casting lines are equipped with automated casting conveyor with laser based speed control to control the size of the ingots, a cooling chamber, automated bundling of ingots, on-line weighing scales for weighment of bundles, automatic strapping and unloading system. The ICMs rated to produce 25 tonne of ingots per hour. The first casting line was commissioned on April 2008. All the 3 ICMs are in operation since October 2008. |

| |

| Billet Casting Machine |

The billet casting facility is equipped with state of the art and fully automated Wagstaff Maxicast Hot Top Billet casting machine. It has all the latest features like Air Slip Air casting process; Auto Cast automated casting control system, Rapid Fill metal distribution system. The mould toolings include ShurFlow Casting rings and DualJet Enhanced Cooling Technology. The casting machine is designed for a casting rate of 60 tonne of per hour and is one of the biggest installations of wagstaff. This facility is under commissioning and the first full length cast was done on July 2009. The tooling details are as given below- |

| |

| Diameter |

No. of strands |

Maximum Length (finished) |

| 178 mm |

116 |

6000 mm |

| 203 mm |

90 |

6000 mm |

| 229 mm |

72 |

6000 mm |

|

| |

| Slab Casting Machine |

The slab casting facility is equipped with best in class Wagstaff Epsilon Ingot casting machine. It has features like Shurcast casting machine, Auto Cast casting control system, 5 strand Laund Air cooled distribution trough, Laser sensors coupled with motorized actuators for mold metal level control. It has got Epsilon moulds with Split Jet Enhanced Cooling Technology to control butt curl. This facility is under erection and expected to be commissioned by September 2009. The mould tooling details are as given below. |

| Size (width x thickness) |

No. of strands |

Maximum Length |

| 410 mm x 1620 mm |

5 |

6000 mm |

| 410 mm x 1540 mm |

5 |

6000 mm |

| 410 mm x 1270 mm |

5 |

6000 mm |

|

| |

| Wire rod Mill |

2 Wire Rod Mills supplied by SOUTHWIRE are in the process of getting erected. It has got 10 stand MORGAN “No –Twist” rolling mill. The production rate of each mill is 8 tonne per hour. The first wire rod line is expected to be commissioned soon. The specification of the rod and coil to be produced out of this facility is as given below- |

| Finished rod diameters (mm) |

Coil ID, OD & Width (mm) |

Maximum Weight (Kg) |

| 9.52, 12, 15 |

560, 1770, 850 |

3400 |

|

| |

| In-line Treatment Facilities |

All the casting lines for value added products like Slab, Billet and Wire rod are equipped with in-line treatment facilities to remove dissolved hydrogen and inclusions from the molten aluminium. The billet and slab facilities have SNIF P180U/I and P140U/I degasser units respectively supplied by SNIF, Pyrotek. The SNIF degassers are coupled with SIVEX 23 Double CFF systems from Pyrotek to ensure best quality metal to the casting facility.

The wire rod line has got STAS degasser and SELEE CFF systems for degassing and filtration.

|

| |

| Homogenizing Furnace |

All the billets will be sold in the homogenized condition. For that purpose 5 electrically heated furnaces of 40 ton capacity each are available. These furnaces have automatic temperature control system for precise control of temperature. An electrically driven mechanical charging car of 55 ton capacity is available to load and unload billets from the homogenizing furnaces. There are two cooling chambers for controlled cooling of billets following the homogenization. 2 homogenizing furnaces and one cooling chamber is in operation. |

| |

| Finishing line |

Cutting facilities are available for cutting head and butt portions of slab and billets. The cutting lines are fully automated and supplied by SERMAS. On-line weighing machines are incorporated in the cutting machine. |

| |

| Products |

| Standard Ingots |

Name: VEDANTAL Name: VEDANTAL

Types: High purity Ingots (HP) / EC Grade Ingots (EC)/Commercial Grade Ingots (CG)

Size: 114mm (thick) x 170mm (width) x 740mm (length)

Weight: 23 Kg each on an average

Bundle size: 740mm (breadth) x 740mm (width) x 980-1090 mm (height)

The Standard Ingots are registered in LME in the name of VEDANTAL. |

| |

| PRODUCT CODE |

QUALITY SPECIFICATIONS |

PRODUCT DESCRIPTION |

| IP11997 |

% Fe ≤ 0.20, % Si ≤ 0.10, % Ti ≤ 0.03, % V ≤ 0.03, % Mn ≤ 0.03, % Zn ≤ 0.03, % Cu ≤ 0.03, % Cr ≤ 0.03, % Zr ≤ 0.03, % B ≤ 0.03, % Ga ≤ 0.04, % Na ≤ 0.03, % Others (total) ≤ 0.10, % Al ≥ 99.70 |

HP Grade Aluminium Ingots (P1020) |

| IE11997 |

% Fe ≤ 0.20, % Si ≤ 0.10, % Mn ≤ 0.01, % Cu ≤ 0.04, % Cr ≤ 0.01, % Zr ≤ 0.01, % (Ti + V) ≤ 0.02, % Al ≥ 99.70 |

EC Grade Aluminium Ingots (EC-1) |

| IE11996 |

% Fe ≤ 0.30, % Si ≤ 0.12, % Mn ≤ 0.01, % Cu ≤ 0.04, % Cr ≤ 0.01, % Zr ≤ 0.01, % (Ti + V) ≤ 0.02, % Al ≥ 99.60 |

EC Grade Aluminium Ingots (EC-2) |

| IC11995 |

% Fe ≤ 0.40, % Si ≤ 0.30, % Al ≥ 99.50 |

CG Grade Aluminium Ingots (CG-1) |

| IC11990 |

% Fe ≤ 0.60, % Si ≤ 0.40, % Al ≥ 99.00 |

CG Grade Aluminium Ingots (CG-G) |

|

| |

| Extrusion Ingots (Billet) |

Alloy : AA6xxx series

Type : Homogenized and sawn billets

Packing : Strapped on wooden runners. The number of

Pieces in each bundle and bundle weight will depend upon the cut length |

| Diameter |

Length |

Squareness |

| 178 ± 1.5 mm |

Up to 6000 mm ± 5 mm |

1mm per 100 mm diameter |

| 203 ± 1.5 mm |

| 229 ± 1.5 mm |

|

| |

Molten aluminium from the electrolytic cells is tapped, transported and transferred to holding furnaces in Cast house with a specially designed vehicle from

M/s Hencon, Netherland. This is first of its kind in India and

it ensures fastest mode of metal transfer from pot line to

cast house with minimum loss of sensible heat.

Molten aluminium from the electrolytic cells is tapped, transported and transferred to holding furnaces in Cast house with a specially designed vehicle from

M/s Hencon, Netherland. This is first of its kind in India and

it ensures fastest mode of metal transfer from pot line to

cast house with minimum loss of sensible heat.

10 furnaces are available each having 60 tonne of molten

aluminium holding capacity. All are electrically heated furnaces, equipped with hydraulic tilting mechanism

and laser sensor based automatic tilting control. The Electrical

furnaces facilitates clean and fumes free environment inside the

cast house. Out of the 10 furnaces, 4 are dedicated to three Ingot

casting lines, 2 for two Wire rod mills, 2 for one Sheet Ingot

Casting machine, and another 2 for one Billet casting machine.

The first furnace was commissioned on March 2008. At present 7 furnaces are operative.

10 furnaces are available each having 60 tonne of molten

aluminium holding capacity. All are electrically heated furnaces, equipped with hydraulic tilting mechanism

and laser sensor based automatic tilting control. The Electrical

furnaces facilitates clean and fumes free environment inside the

cast house. Out of the 10 furnaces, 4 are dedicated to three Ingot

casting lines, 2 for two Wire rod mills, 2 for one Sheet Ingot

Casting machine, and another 2 for one Billet casting machine.

The first furnace was commissioned on March 2008. At present 7 furnaces are operative. 3 fully automated Ingot casting lines of Befesa make are available for casting of standard ingots. These casting lines are equipped with automated casting conveyor with laser based speed control to control the size of the ingots, a cooling chamber, automated bundling of ingots, on-line weighing scales for weighment of bundles, automatic strapping and unloading system. The ICMs rated to produce 25 tonne of ingots per hour. The first casting line was commissioned on April 2008. All the 3 ICMs are in operation since October 2008.

3 fully automated Ingot casting lines of Befesa make are available for casting of standard ingots. These casting lines are equipped with automated casting conveyor with laser based speed control to control the size of the ingots, a cooling chamber, automated bundling of ingots, on-line weighing scales for weighment of bundles, automatic strapping and unloading system. The ICMs rated to produce 25 tonne of ingots per hour. The first casting line was commissioned on April 2008. All the 3 ICMs are in operation since October 2008. The billet casting facility is equipped with state of the art and fully automated Wagstaff Maxicast Hot Top Billet casting machine. It has all the latest features like Air Slip Air casting process; Auto Cast automated casting control system, Rapid Fill metal distribution system. The mould toolings include ShurFlow Casting rings and DualJet Enhanced Cooling Technology. The casting machine is designed for a casting rate of 60 tonne of per hour and is one of the biggest installations of wagstaff. This facility is under commissioning and the first full length cast was done on July 2009. The tooling details are as given below-

The billet casting facility is equipped with state of the art and fully automated Wagstaff Maxicast Hot Top Billet casting machine. It has all the latest features like Air Slip Air casting process; Auto Cast automated casting control system, Rapid Fill metal distribution system. The mould toolings include ShurFlow Casting rings and DualJet Enhanced Cooling Technology. The casting machine is designed for a casting rate of 60 tonne of per hour and is one of the biggest installations of wagstaff. This facility is under commissioning and the first full length cast was done on July 2009. The tooling details are as given below- Name:

Name: